BLIND TYPES

- Plain Panel Glides – plain fabric panels (no extrusion or battens attached)

- Sewless Panel Glide, gives the same look as a Roman blind using aluminium back battens

- Plantation Panel Glide are fabric panels with timber battens on the front and back of each panel to create a feature

OVERVIEW

Panel Glide blinds provide an ideal solution for covering large windows and sliding doors, and can also be used as a room divider. The panels are designed to overlap to minimise light penetration, making it a good option for rooms that require less light.

OPERATION

Wand with swivel clip attached to the lead panel

LIMITATION

- Maximum Width : 5410mm

- Minimum Width : 610mm

- Maximum Drop : 3200mm

- Minimum Drop : 600mm

PANEL SIZES

- Minimum Panel width 180mm plus overlap

- Minimum 2 Panels

- Recommended panel width 450 – 900mm

- Maximum panel width 1200mm

PANEL OVERLAP

50-70mm

TRACK

- Powder coated aluminium extrusion Polypropylene Sliders

- Supplied in 2 pieces if opening is wider than 3000mm (3 metres) with a track joiner

TRACK DIMENSIONS

- 2 Panels : 40mm wide x 16mm deep

- 3 Panels : 51mm wide x 16mm deep

- 4 Panels : 69mm wide x 16mm deep

- 5 Panels : 87mm wide x 16mm deep

TRACK PROJECTION (OUTSIDE MOUNT)

- 2 Panels : 75mm

- 3 Panels : 75mm

- 4 Panels : 85mm

- 5 Panels : 100mm

WAND & TRACK COLOUR

Available in White, Grey or Black

EXTENSION BRACKETS

L-shape powder coated bracket with adjustable spring clip

TIMBER BATTEN COLOURS (Plantation)

Front of Panel : Half round profile 12mm wide x 8mm deep

Back of Panel : Flat Profile 12mm wide x 5mm deep

Rear battens will be colour matched, unless otherwise specified

BACK EXTRUSIONS (Sewless)

Aluminium off white colour

BASE BAR (all styles)

Plain Trim Basebar – Standard

FLAT FABRIC COVERED BASEBAR – SURCHARGE

FABRIC CUTTING

No side hems

FABRIC ATTACHMENT METHOD

All styles of panels are attached to the track slider with Velcro

PANEL GLIDE SPECIFICATIONS

SETTLING OUT

Only Sewless style panels will be subject to settling/stretching process over a period of time.

Note : The settling process could vary the drop by at least 10mm.

The factory makes no allowance for this process please consider this when measuring for Panel Glides using the Sewless option.

FABRIC APPEARANCE

The sewless style of panels will sometimes show very slight puckering of fabric. This is unavoidable due to the tension placed on the fabric from the splining (tucking) process.

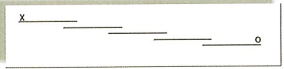

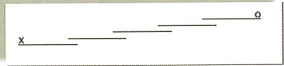

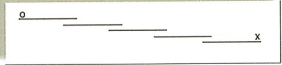

LAYOUT OPTIONS

Panel layout (direction of stacking & drawing). X = fixed panel : O = wand position

Layout A : Drawing panels to open from Right to Left stacking to the front

Layout B : Drawing panels to open from Right to Left stacking to the back

Layout C : Drawing panels to open from Left to Right stacking to the back

Layout D : Drawing panels to open from Left to Right stacking to the front

Layout E : Drawing panels to open from center to the left and right stacking to the back

Layout F : Drawing panels to open from center to the left and right stacking to the front

STANDARD TOLERANCE

Please note that our standard tolerance for blind width and blind drop is +- 5mm. If the blind is made within our tolerance range, no claim will be accepted.

FABRIC PATTERNS

For a patterned fabric, the pattern grain won’t usually line up perfectly with the horizontal or vertical edge of the blind. Except to see a variation from one side to the other.

OVERALL MEASUREMENTS

It will be assumed that all the provided sizes will be subject to factory deduction. (unless otherwise specified on the order)

CUPPING

Panel glides with blockout fabrics will usually show some cupping on each of the vertical edges. Cupping of up to a few millimeters will be considered within acceptable allowance (+/-15mm).

GENERAL MAINTENANCE

Most Panel Glides simply regular vacuuming with an upholstery attachment.

STAIN REMOVAL

To remove, sponge blind clean with a damp cloth. Use diluted washing liquid in warm water & avoid rubbing the stain. Do not immerse blinds in water.

SPOT CLEANING

Small dry marks may be rubbed off with a gum-based eraser.